European products Detection process

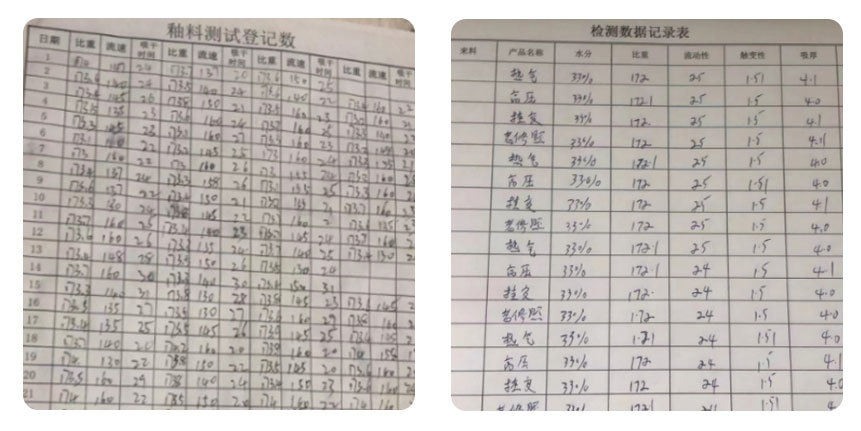

Test the purchased glaze and slurry to ensure product quality from the source

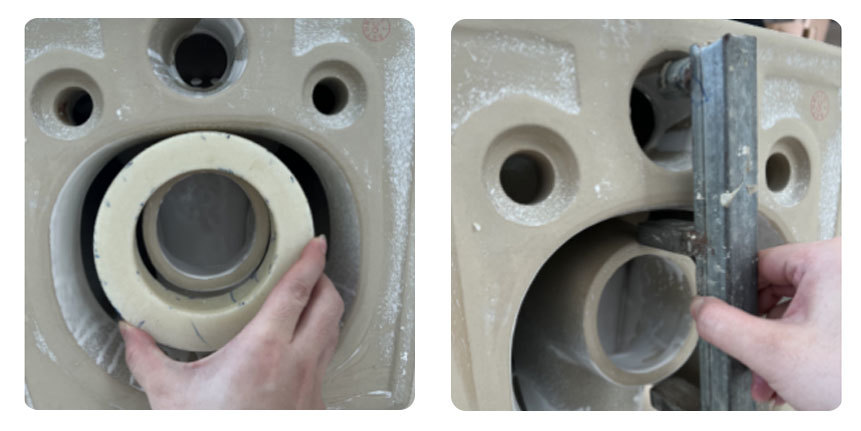

Using precision punching tools to ensure more stable quality of each product produced

Use specific calibration tools to test the accuracy of hole positions in various aspects of toilet hanging/separating systems

Equipped with a laboratory to conduct the following functional tests on the finished product: water absorption test/anti freezing crack test/water content measurement

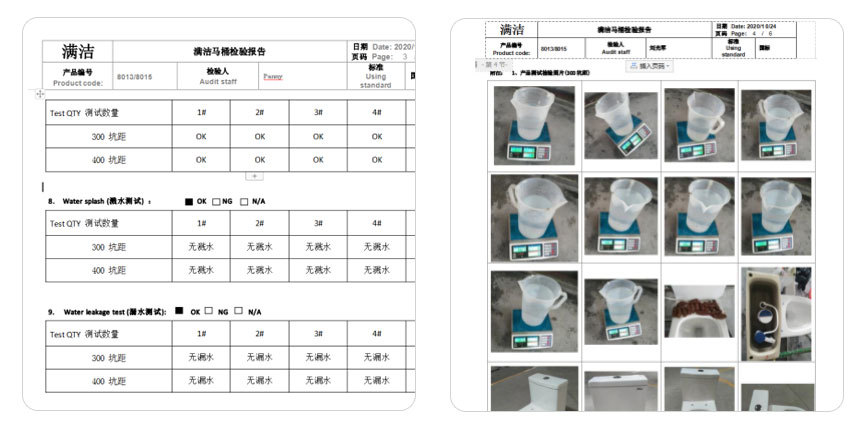

In order to prevent missed inspections, quality inspectors and sales representatives will conduct spot checks on each product before shipment and fill out a spot check report. If any problems are found, improvements will be made in a timely manner.

Export to Australia: WM certification

Manjie Bathroom currently has WM certification, and all products certified by WM in the factory must strictly comply with Australian inspection standards. This includes using precision tools to accurately punch holes in the prototype, ensuring that each product has a highly unified utility; Secondly, water testing is conducted using "Australian paper" that meets Australian standards, to help Australian customers better understand the flushing efficiency of toilets.